The historic steam-powered sawmill complex of the Hull-Oakes Lumber Company occupies approximately twenty-eight acres on the east slope of the Coast Range in Monroe. Timber industry trade groups, including the Western Wood Products Association in Portland, consider the mill to be one of the last commercially viable steam-powered long and large log sawmills in the country—possibly the last such sawmill. National Register of Historic Places status in 1996 recognizes the mill’s regional importance as a rare example of a working mill that uses lumber manufacturing equipment and methods characteristic of the Steam Age.

Timberman Ralph Hull built the mill in the winter of 1938-1939 as the Ralph Hull Lumber Company. Hull was born on April 13, 1912, in an area known as Hell's Canyon northwest of Monroe. His family raised cattle, goats, and sheep, and Hull grew up logging on the family's stump ranch. He also observed his relatives working in the sawmill business and decided that sawmilling was the career for him.

In quick succession, beginning in 1934, Hull operated three mills near Monroe (two of them burned down). Hull bought the remains of his cousin Wes Miller’s sawmill and built the present mill on a former Southern Pacific railhead known as Dawson Station, a site occupied by sawmills since 1919. Three corporate configurations have guided the plant since 1955, the year Hull teamed up with Chester Oakes, a long-time logger in the area and Hull's brother-in-law.

Traditionally, steam engines muscled the sawmills, making lumber on factory floors where workers courted death and injury amid flapping belts, chains, and vibrating bedlam. Computers and lasers frequently guide today’s lumber mills, which are considerably safer and quieter. Built in the vernacular tradition without benefit of formal plans, Ralph Hull’s mill is a rough-hewn place where function trumps form. Four steam engines initially drove the Depression-era plant. When electricity arrived in the 1950s, Hull gradually switched some systems to electrical power.

Built of heavy timbers, the sawmill contains massive machinery capable of sustaining the stresses of processing logs that weigh more than five tons. Twin boilers producing 150 pounds of steam drive a twin cylinder, eight-ton, 1906 Ames Iron Works steam engine that powers the mill’s primary lumber-cutting saw. A secondary steam engine powers the mill's log carriage, which moves logs through the primary saw. Steam still drives 50 percent of the mill.

Mill output traditionally consists of dimension lumber and specialty products that involve the cutting in one pass of logs up to nine feet in diameter and eighty-five feet long to produce large Douglas-fir timbers. Custom-milled products have included bridge stringers, gold dredge beams, support planks for restoration of the frigate the U.S.S. Constitution, and lumber to rebuild the 1895 lumber schooner C.A. Thayer, which ison display at San Francisco’s Maritime Museum. Entering the second decade of the twenty-first century, the mill produces slightly more than twenty million board feet of lumber a year—about half that in timbers.

Throughout its history, the labor-intensive mill has employed about sixty-five people, who have significantly contributed to Benton County's economy.The mill was a stabilizing influence for the county’s economy during the Great Depression and World War II, and it provided steady jobs and products that were sold worldwide after the war. The Hull-Oakes Lumber Company mill is now run by Hull’s grandson, Todd Nystrom.

-

![Debris fed into furnace below boiler, Hull-Oakes Lumber Mill, Feb. 2011.]()

Hull-Oakes Mill 19.

Debris fed into furnace below boiler, Hull-Oakes Lumber Mill, Feb. 2011. Photo Gary Katz, copyright thisiscarpentry.com

-

![Squaring-up the timber, Hull-Oakes Lumber Mill, Feb. 2011.]()

Hull-Oakes Mill 9.

Squaring-up the timber, Hull-Oakes Lumber Mill, Feb. 2011. Photo Gary Katz, copyright thisiscarpentry.com

-

![Cutting timbers, Hull-Oakes Lumber Mill, Feb. 2011.]()

Hull-Oakes Mill 10.

Cutting timbers, Hull-Oakes Lumber Mill, Feb. 2011. Photo Gary Katz, copyright thisiscarpentry.com

-

![Debris chipper, Hull-Oakes Lumber Mill, Feb. 2011.]()

Hull-Oakes Mill 11.

Debris chipper, Hull-Oakes Lumber Mill, Feb. 2011. Photo Gary Katz, copyright thisiscarpentry.com

-

![Lumber carrier with finished dimensional lumber, Hull-Oakes Lumber Mill, Feb. 2011.]()

Hull-Oakes Mill 12.

Lumber carrier with finished dimensional lumber, Hull-Oakes Lumber Mill, Feb. 2011. Photo Gary Katz, copyright thisiscarpentry.com

-

![Bandsaw, Hull-Oakes Lumber Mill, Feb. 2011.]()

Hull-Oakes Mill 13.

Bandsaw, Hull-Oakes Lumber Mill, Feb. 2011. Photo Gary Katz, copyright thisiscarpentry.com

-

![Sharpening bandsaw blade, Hull-Oakes Lumber Mill, Feb. 2011.]()

Hull-Oakes Mill 14.

Sharpening bandsaw blade, Hull-Oakes Lumber Mill, Feb. 2011. Photo Gary Katz, copyright thisiscarpentry.com

-

![Sharpening bandsaw blade, Hull-Oakes Lumber Mill, Feb. 2011.]()

Hull-Oakes Mill 15.

Sharpening bandsaw blade, Hull-Oakes Lumber Mill, Feb. 2011. Photo Gary Katz, copyright thisiscarpentry.com

-

![Old boiler currently used to store water, Hull-Oakes Lumber Mill, Feb. 2011.]()

Hull-Oakes Mill 16.

Old boiler currently used to store water, Hull-Oakes Lumber Mill, Feb. 2011. Photo Gary Katz, copyright thisiscarpentry.com

-

![Log being cut, Hull-Oakes Lumber Mill, Feb. 2011.]()

Hull-Oakes Mill 8.

Log being cut, Hull-Oakes Lumber Mill, Feb. 2011. Photo Gary Katz, copyright thisiscarpentry.com

-

![De-barking logs, Hull-Oakes Lumber Mill, Feb. 2011.]()

Hull-Oakes Mill 7.

De-barking logs, Hull-Oakes Lumber Mill, Feb. 2011. Photo Gary Katz, copyright thisiscarpentry.com

-

![Steam engine, Hull-Oakes Lumber Mill, Feb. 2011.]()

Hull-Oakes Mill 20.

Steam engine, Hull-Oakes Lumber Mill, Feb. 2011. Photo Gary Katz, copyright thisiscarpentry.com

-

![Gears for various equipment, Hull-Oakes Lumber Mill, Feb. 2011.]()

Hull-Oakes Mill 21.

Gears for various equipment, Hull-Oakes Lumber Mill, Feb. 2011. Photo Gary Katz, copyright thisiscarpentry.com

-

![Finished timbers ready for shipment, Hull-Oakes Lumber Mill, Feb. 2011.]()

Hull-Oakes Mill 22.

Finished timbers ready for shipment, Hull-Oakes Lumber Mill, Feb. 2011. Photo Gary Katz, copyright thisiscarpentry.com

-

![Approaching Hull-Oakes Lumber Mill from the east on Dawson Road, Feb. 2011.]()

Hull-Oakes Mill 1.

Approaching Hull-Oakes Lumber Mill from the east on Dawson Road, Feb. 2011. Photo Gary Katz, copyright thisiscarpentry.com

-

![Unloading logs from trucks at Hull-Oakes Lumber Mill, Feb. 2011.]()

Hull-Oakes Mill 2.

Unloading logs from trucks at Hull-Oakes Lumber Mill, Feb. 2011. Photo Gary Katz, copyright thisiscarpentry.com

-

![Sorting logs in pond at Hull-Oakes Lumber Mill, Feb. 2011.]()

Hull-Oakes Mill 3.

Sorting logs in pond at Hull-Oakes Lumber Mill, Feb. 2011. Photo Gary Katz, copyright thisiscarpentry.com

-

![Debris being routed to chipper, Hull-Oakes Lumber Mill, Feb. 2011.]()

Hull-Oakes Mill 4.

Debris being routed to chipper, Hull-Oakes Lumber Mill, Feb. 2011. Photo Gary Katz, copyright thisiscarpentry.com

-

![Log-lift hoisting logs out of pond, Hull-Oakes Lumber Mill, Feb. 2011.]()

Hull-Oakes Mill 6.

Log-lift hoisting logs out of pond, Hull-Oakes Lumber Mill, Feb. 2011. Photo Gary Katz, copyright thisiscarpentry.com

-

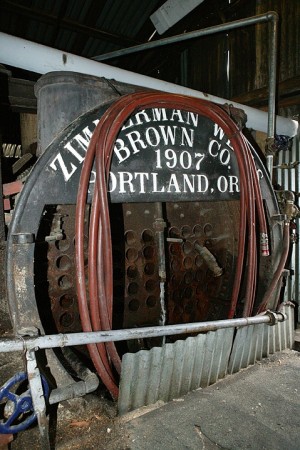

![Boiler, Hull-Oakes Lumber Mill, Feb. 2011.]()

Hull-Oakes Mill 17.

Boiler, Hull-Oakes Lumber Mill, Feb. 2011. Photo Gary Katz, copyright thisiscarpentry.com

Related Entries

-

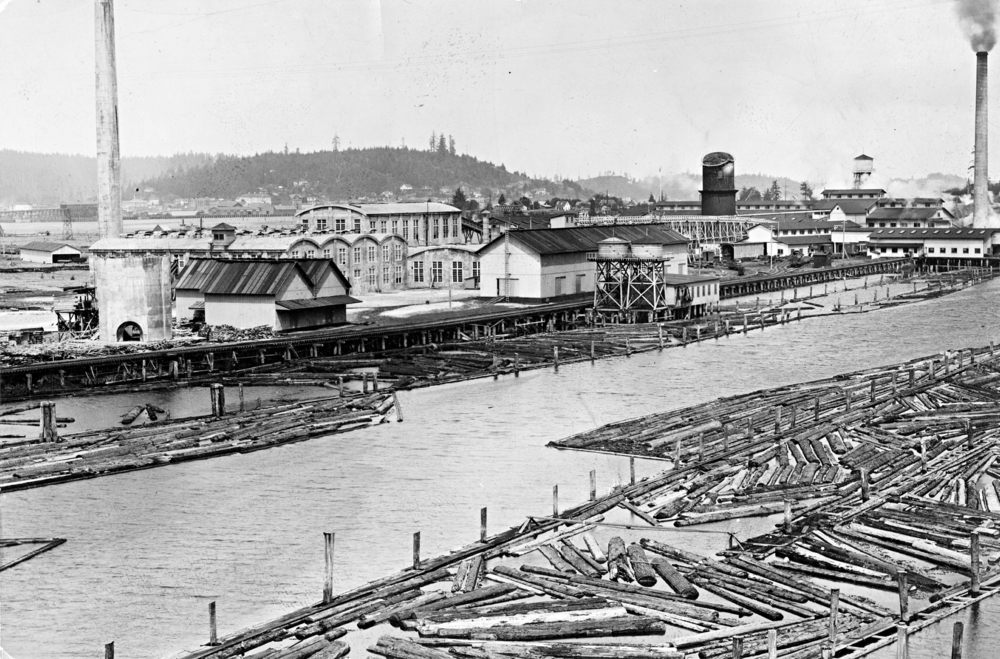

![C.A. Smith Lumber Company]()

C.A. Smith Lumber Company

Charles Axel Smith became, for a time, one of Oregon's most powerful lu…

-

Hines and the Edward Hines Lumber Company

In the mid-1920s, large sawmill owners in the United States found a new…

-

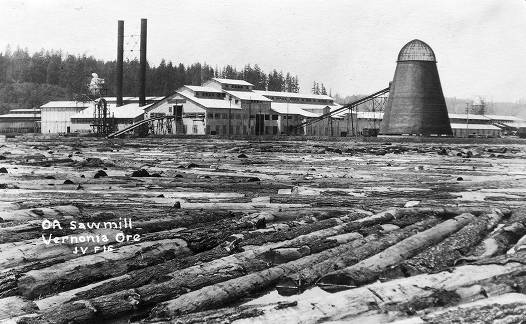

![Oregon-American Lumber Company]()

Oregon-American Lumber Company

The Oregon-American Lumber Company (1917-1934) and its successors—the O…

-

![Timber Industry]()

Timber Industry

Since the 1880s, long before the mythical Paul Bunyan roamed the Northw…

Related Historical Records

Map This on the Oregon History WayFinder

The Oregon History Wayfinder is an interactive map that identifies significant places, people, and events in Oregon history.

Further Reading

Katz, Gary. "Hull-Oaks Sawmill." thisiscarpentry.com, Feb. 25, 2011. http://www.thisiscarpentry.com/2011/02/25/hull-oaks-sawmill/.

Wisner, George B. "Hull-Oakes Lumber Company's Steam-Powered Sawmill: A Case Study in Industrial Archaeology." In Anthropology Northwest Number 10, edited by David R. Brauner. Corvallis. Department of Anthropology, Oregon State University, 1998.